close

Choose Your Site

Global

Social Media

| Packaging : | |

|---|---|

| Feature: | |

| Surface treatment: | |

| Availability: | |

| Quantity: | |

Product description

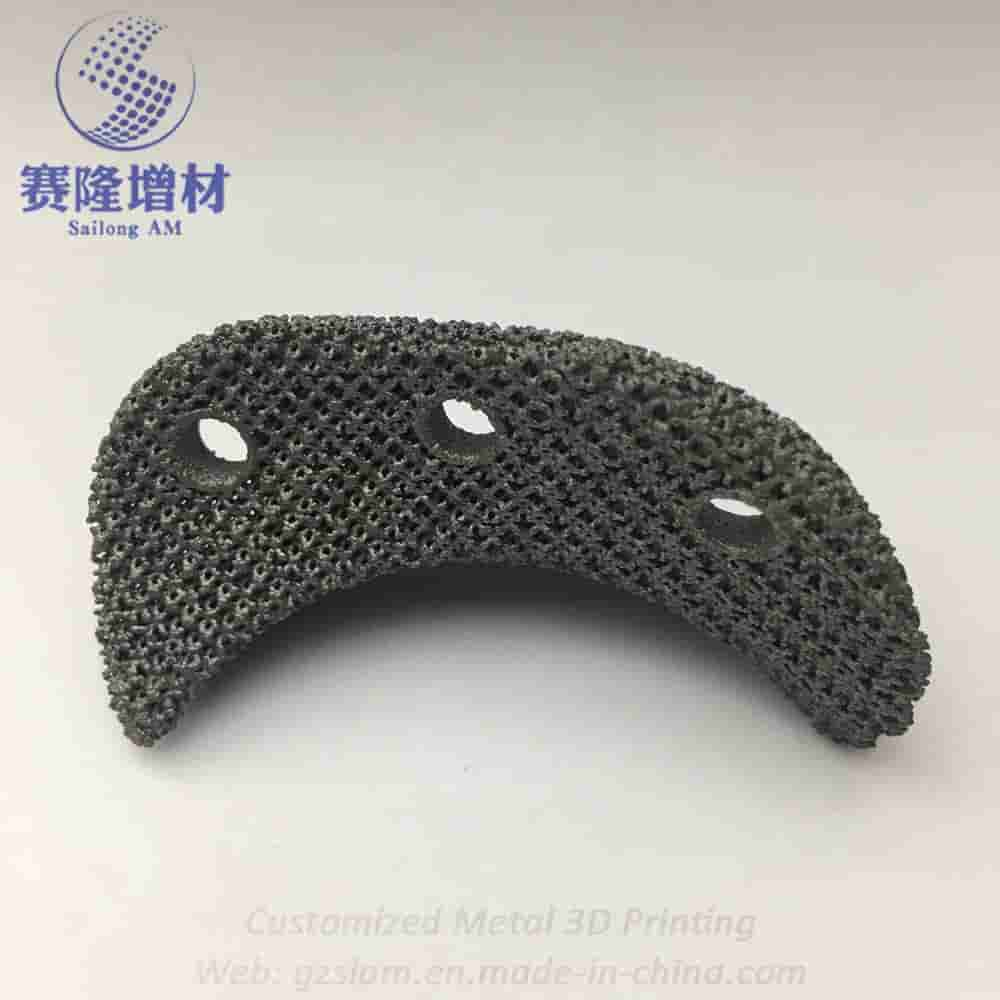

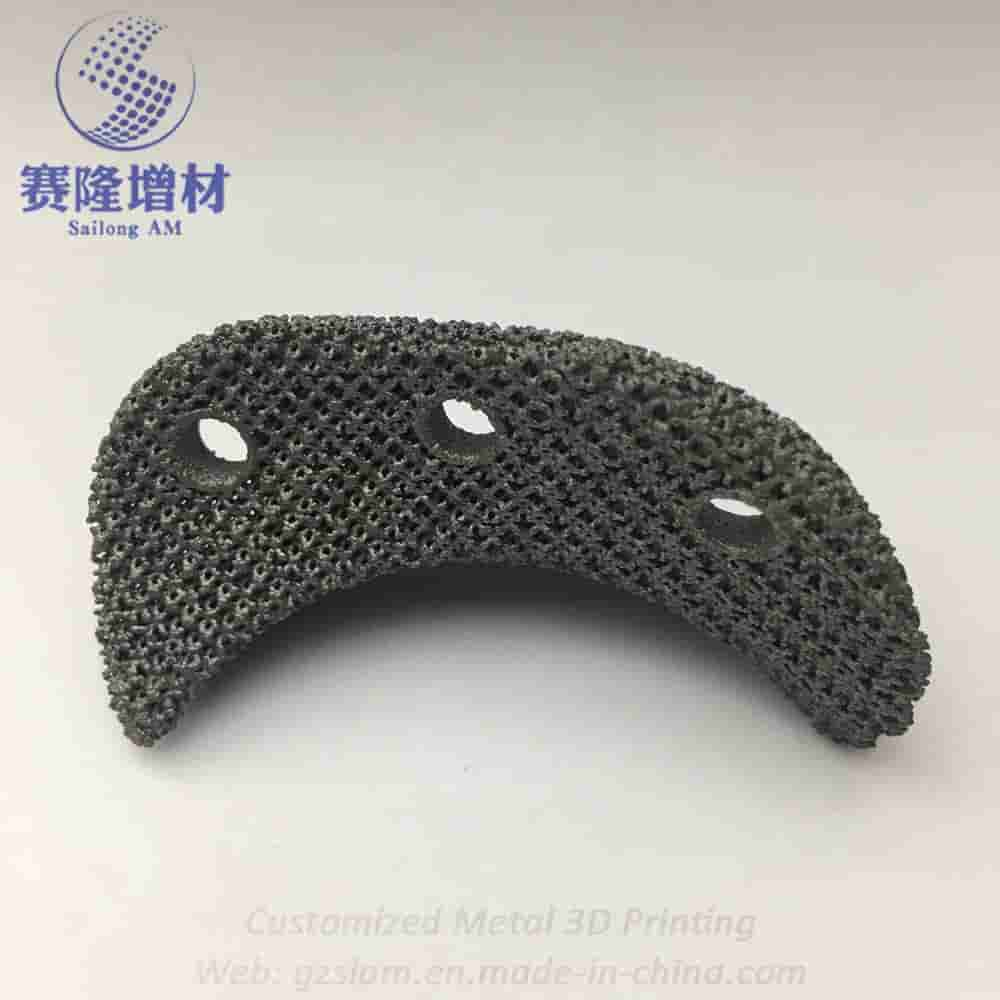

Human implants belong to Class III medical appliances, which require high biocompatibility, mechanical properties, non-toxicity and anti-corrosion properties. Implantable artificial bones are mainly used in the treatment of bone tumors, spinal trauma and bone defects. Additive manufacturing orthopaedics has attracted much attention because of its individualized, complex, accurate production and rapid response. Its commonly used materials include metal materials such as titanium-based alloys, cobalt-chromium alloys, stainless steel, tantalum and non-metallic materials such as PEEK materials, hydroxyapatite and so on. Through three-dimensional reconstruction of medical CT data, porous implants with bionic trabecular structures such as joint, spine, craniofacial bone and extremities can be manufactured by using three-dimensional printing techniques like electron beam melting, selective laser melting and selective laser sintering. The factors such as porosity, pore size and pore reinforcement can be adjusted for individuals, which is more conducive to bone growth and is better in clinical effect.

As surgical implant materials, titanium and its alloys have many advantages, such as low density, high strength, good toughness, good biocompatibility, non-toxic, low elastic modulus, good corrosion resistance, low X-ray absorption rate, etc., so they play an increasingly important role in medical metal materials.

Since its successful development, Ti-Ni alloy with unique shape memory properties has been used in stomatology, neurosurgery, cardiovascular surgery, thoracic surgery, otolaryngology, hepatobiliary surgery, urology and gynecology, etc. The products include dental orthotic wire, root canal file, spinal orthotic rod, bone plate, intramedullary needle, patella claw, guide wire, guide needle, heart patch, vascular stent, thrombus filter, esophageal stent, respiratory stent, biliary stent, urethral stent, rectal stent, duodenal stent, external ear canal stent, IUD and so on

1. Highly accurate technology,All products are tested with three-dimensional measurement

2. Provide products specific diameters and tapers according to clinical needs

3. More than 1,000 clinical applications of Titanium alloy implant and The world's most customized clinical application of porous sputum

Product parameters

| Pore size | 0.4~0.6 mm |

| Porosity | 70%~85% |

| Material | Titanium and Titanium alloy; Base metal |

| specification | Personalized customization |

Company exhibition

Guangzhou Sailong Additives Manufacturing Co., Ltd.Was jointly sponsored by Northwest Nonferrous Metal Research Institute, Xi'an Sailong Metal Materials Co., Ltd.And State Key Laboratory of Metallic Porous Materials, and a high-tech enterprise led by core members of the technical team.The company's entrepreneurial team is led by Professor Tang Huiping, director of the National Key Laboratory of Metals and Porous Materials, and Wang Qiang, deputy director of the State Key Laboratory of Metallic Porous Materials.Professor Tang Huiping is the chairman of the company, and Dr.Wang Qiangbing is the general manager of the company.The company has more than 90% of the graduates.

The company is mainly engaged in the design, development, production and sales of additive manufacturing products and raw materials, including 3D printing parts, powder metallurgy products, refining and chemical production special equipment manufacturing.Products have been widely used in aerospace, medical, mold and other fields.

Service advantages

1. We are manufacturer and have our own factory

2. Customized design is avaiable, OEM & ODM are welcomed

3. Best after service: 1year warranty and lifetime service

4. Prefession and Hardworking Team, reply your inquiry in 24 hours

Certificate

FAQ

Q1. How about your delivery time?

A: Generally, it will take 8 to 15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q2. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q3. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q4. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q5: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them no matter where they come from.

Product description

Human implants belong to Class III medical appliances, which require high biocompatibility, mechanical properties, non-toxicity and anti-corrosion properties. Implantable artificial bones are mainly used in the treatment of bone tumors, spinal trauma and bone defects. Additive manufacturing orthopaedics has attracted much attention because of its individualized, complex, accurate production and rapid response. Its commonly used materials include metal materials such as titanium-based alloys, cobalt-chromium alloys, stainless steel, tantalum and non-metallic materials such as PEEK materials, hydroxyapatite and so on. Through three-dimensional reconstruction of medical CT data, porous implants with bionic trabecular structures such as joint, spine, craniofacial bone and extremities can be manufactured by using three-dimensional printing techniques like electron beam melting, selective laser melting and selective laser sintering. The factors such as porosity, pore size and pore reinforcement can be adjusted for individuals, which is more conducive to bone growth and is better in clinical effect.

As surgical implant materials, titanium and its alloys have many advantages, such as low density, high strength, good toughness, good biocompatibility, non-toxic, low elastic modulus, good corrosion resistance, low X-ray absorption rate, etc., so they play an increasingly important role in medical metal materials.

Since its successful development, Ti-Ni alloy with unique shape memory properties has been used in stomatology, neurosurgery, cardiovascular surgery, thoracic surgery, otolaryngology, hepatobiliary surgery, urology and gynecology, etc. The products include dental orthotic wire, root canal file, spinal orthotic rod, bone plate, intramedullary needle, patella claw, guide wire, guide needle, heart patch, vascular stent, thrombus filter, esophageal stent, respiratory stent, biliary stent, urethral stent, rectal stent, duodenal stent, external ear canal stent, IUD and so on

1. Highly accurate technology,All products are tested with three-dimensional measurement

2. Provide products specific diameters and tapers according to clinical needs

3. More than 1,000 clinical applications of Titanium alloy implant and The world's most customized clinical application of porous sputum

Product parameters

| Pore size | 0.4~0.6 mm |

| Porosity | 70%~85% |

| Material | Titanium and Titanium alloy; Base metal |

| specification | Personalized customization |

Company exhibition

Guangzhou Sailong Additives Manufacturing Co., Ltd.Was jointly sponsored by Northwest Nonferrous Metal Research Institute, Xi'an Sailong Metal Materials Co., Ltd.And State Key Laboratory of Metallic Porous Materials, and a high-tech enterprise led by core members of the technical team.The company's entrepreneurial team is led by Professor Tang Huiping, director of the National Key Laboratory of Metals and Porous Materials, and Wang Qiang, deputy director of the State Key Laboratory of Metallic Porous Materials.Professor Tang Huiping is the chairman of the company, and Dr.Wang Qiangbing is the general manager of the company.The company has more than 90% of the graduates.

The company is mainly engaged in the design, development, production and sales of additive manufacturing products and raw materials, including 3D printing parts, powder metallurgy products, refining and chemical production special equipment manufacturing.Products have been widely used in aerospace, medical, mold and other fields.

Service advantages

1. We are manufacturer and have our own factory

2. Customized design is avaiable, OEM & ODM are welcomed

3. Best after service: 1year warranty and lifetime service

4. Prefession and Hardworking Team, reply your inquiry in 24 hours

Certificate

FAQ

Q1. How about your delivery time?

A: Generally, it will take 8 to 15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q2. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q3. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q4. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q5: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them no matter where they come from.