close

Choose Your Site

Global

Social Media

| Packaging : | |

|---|---|

| Feature : | |

| Material : | |

| Size : | |

| Availability: | |

| Quantity: | |

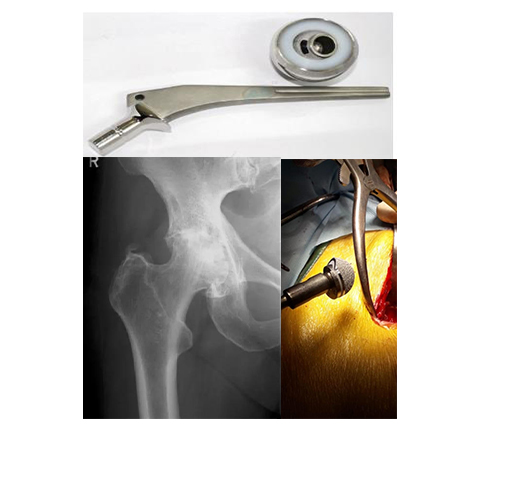

Metal 3D Printing of medical implant

Metal 3D printing removes many of the constraints seen in more traditional manufacturing methods. such as milling, casting or fabrication. This opens up new possibilities for complex geometries and mass customisation of parts, at a commercially viable cost, that were previously unfeasible.

Advantage of medical implement

- Expertise. Co-founded by Northwest Institute for Nonferrous Metal Research and

State Key Laboratory of Porous Metal Materials.

- Experienced. In the past 3 years, we have provided more than 1000 cases of

powder bed electron beam melting 3D printing for more than 20 domestic top three

clinical units in China. The standardized and personalized implants have been

successfully applied.

- Inexpensive. Full service capability with materials, 3D printer and printing services,

minimum the printing costs.

| Material | Advantage |

| Titanium | - Very low specific weight - Corrosion-resistant - Biocompatible |

| Tantalum | - Excellent physical properties - Corrosion-resistant - Biocompatible |

| Cobalt Chrome | - Hard & tough - Corrosion-resistant - Biocompatible |

Applications

The 3D priting implant product was beapplied to clinic surgery for patient. the main character have two points,

firstly the medical product have excellt property that it can improve the wound healing structure and faster conbine

with body. the 3D printing medical products is extremely suit to patient. because of the model organ was designed

the surgery before.it is efficients to save the surgery time and enhances the sick person healing rate.

About us

Our company is jointly sponsored by northwest institute for non-ferrous metal research and state key laboratory of porous metal materials,and is a high-tech enterprise led by core members of the technical team. The company is mainly engaged in the design, development,production and sales of spherical metal powder, powder equipment, metal 3d printing parts,porous metal materials and titanium alloy product,widely used in additive manufacturing,

laser cladding, surface coating, electronic product and other fields.

Certification

Shipping and servicing

Payment

FAQ

Q1. How about your delivery time?

A: Generally, it will take 8 to 15 days after receiving your advance payment. The specific delivery time

depends on the items and the quantity of your order.

Q2. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q3. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay

the sample cost and the courier cost.

Q4. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q5: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them no matter where they come from.

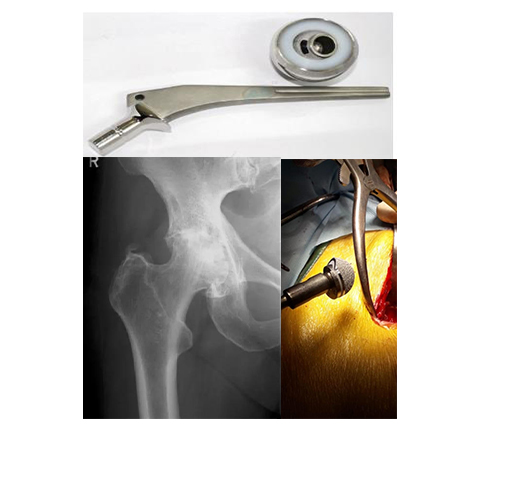

Metal 3D Printing of medical implant

Metal 3D printing removes many of the constraints seen in more traditional manufacturing methods. such as milling, casting or fabrication. This opens up new possibilities for complex geometries and mass customisation of parts, at a commercially viable cost, that were previously unfeasible.

Advantage of medical implement

- Expertise. Co-founded by Northwest Institute for Nonferrous Metal Research and

State Key Laboratory of Porous Metal Materials.

- Experienced. In the past 3 years, we have provided more than 1000 cases of

powder bed electron beam melting 3D printing for more than 20 domestic top three

clinical units in China. The standardized and personalized implants have been

successfully applied.

- Inexpensive. Full service capability with materials, 3D printer and printing services,

minimum the printing costs.

| Material | Advantage |

| Titanium | - Very low specific weight - Corrosion-resistant - Biocompatible |

| Tantalum | - Excellent physical properties - Corrosion-resistant - Biocompatible |

| Cobalt Chrome | - Hard & tough - Corrosion-resistant - Biocompatible |

Applications

The 3D priting implant product was beapplied to clinic surgery for patient. the main character have two points,

firstly the medical product have excellt property that it can improve the wound healing structure and faster conbine

with body. the 3D printing medical products is extremely suit to patient. because of the model organ was designed

the surgery before.it is efficients to save the surgery time and enhances the sick person healing rate.

About us

Our company is jointly sponsored by northwest institute for non-ferrous metal research and state key laboratory of porous metal materials,and is a high-tech enterprise led by core members of the technical team. The company is mainly engaged in the design, development,production and sales of spherical metal powder, powder equipment, metal 3d printing parts,porous metal materials and titanium alloy product,widely used in additive manufacturing,

laser cladding, surface coating, electronic product and other fields.

Certification

Shipping and servicing

Payment

FAQ

Q1. How about your delivery time?

A: Generally, it will take 8 to 15 days after receiving your advance payment. The specific delivery time

depends on the items and the quantity of your order.

Q2. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q3. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay

the sample cost and the courier cost.

Q4. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q5: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them no matter where they come from.